Lead Coated Copper Step Flashing

Metal flashing materials include lead aluminium copper stainless steel zinc alloy other architectural metals or a metal with a coating such as galvanized steel lead coated copper anodized aluminum terne coated copper galvalume aluminum zinc alloy coated sheet steel and metals similar to stone coated metal roofing.

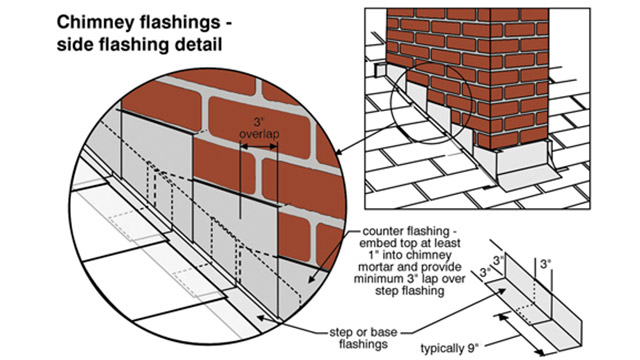

Lead coated copper step flashing. Lead coated copper another popular copper product performs much the same way as ordinary copper but is less reactive so it s often used for flashing galvalume roofing. Copper flashing coated with lead on both sides can work well where staining of building com ponents from runoff may be a problem. The step flashing either keyed or smooth has a vertical locking slot that holds the insert into place. This process completely coats both sides of the copper giving it a silver gray finish.

16 oz 20 oz. Copper stainless steel terne coated s s lead coated copper. Lead coated copper has the same life span as regular copper which is best used as pan flashing or step flashing on long lasting roofs made of tile or slate. Lead coated copper sheeting and flashing combine the positive aspects of both copper and lead yielding a finished product that is superior to other metal roof options in many situations.

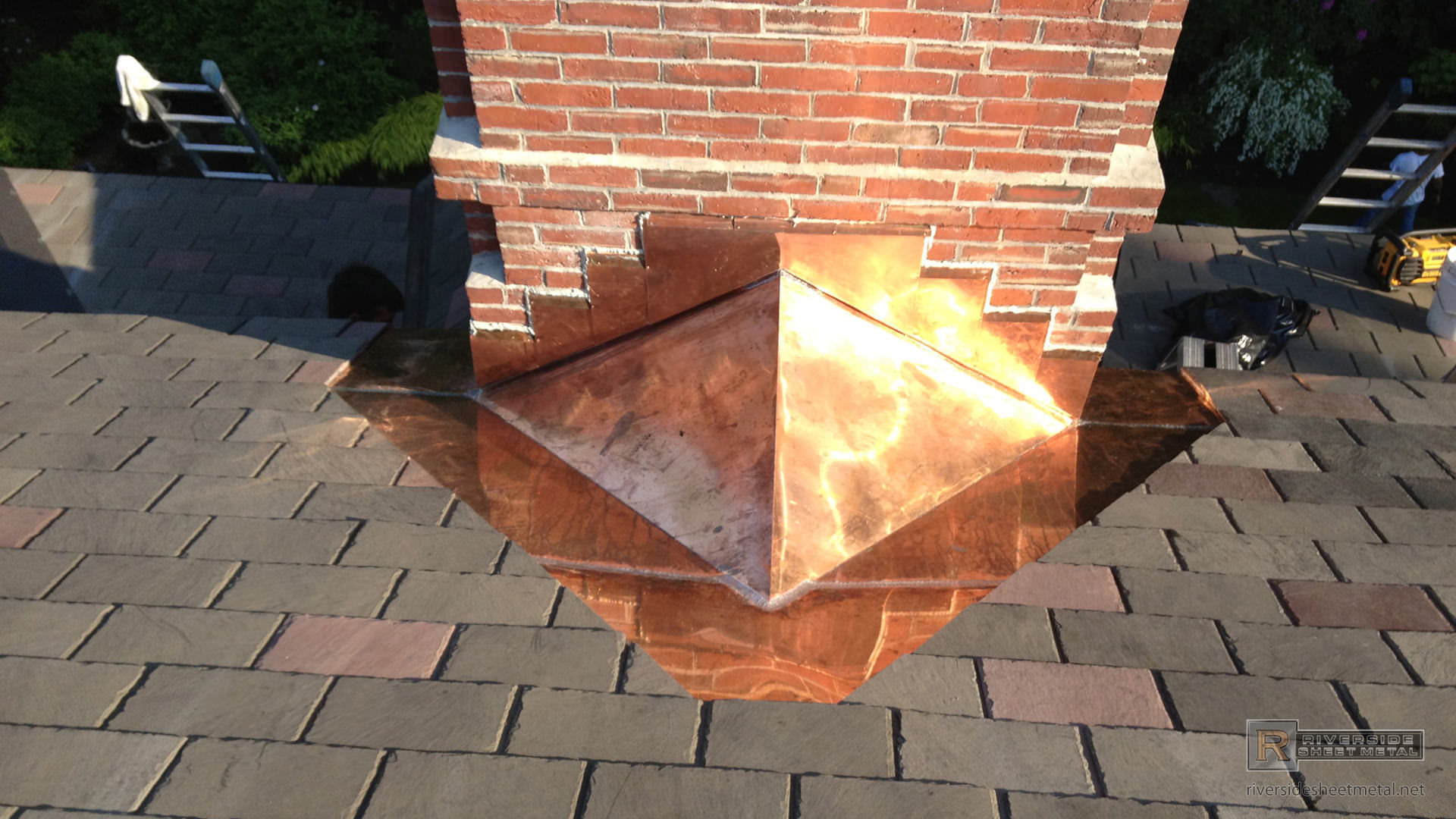

Lead coated copper has been used for over a century in architectural building products and is still available. Used for gutters hangers metal roofing panels downspouts chimney caps cupolas louvers finials edge metal flashing step flashing leader heads gutter accessories conductor boxes and skylights. In valleys on tile wood shake or slate. Downspouts chimney caps cupolas louvers finials edge metal flashing step flashing leader heads gutter accessories conductor boxes and skylights.

Lead coated copper is produced by dipping a copper sheet in hot molten lead coating both sides with. After the step flashing is installed the insert can be set against the base flashing. And along ridges and hips. Copper has been used as a roofing material since medieval times and is still very popular today.

The insert can be removed and reused at any time. Also copper flashing will react in contact with galvanized steel unless the copper is lead coated. Copper flashing is a superstar of the sheet metal flashings. Lead coated copper has a less noticeable gray runoff.

Copper and lead coated copper copper flashing can be used around chimneys. Lead coated copper sheeting combines both copper and lead making it the more superior roofing option.